What does the Tech Spec say about building a perimeter wall for a SCIF or SAPF?

The perimeter walls of a secure facility are a key part of the physical, acoustic and TEMPEST protections, and the ICD 705 Technical Specifications, or Tech Spec, lay out the requirements for building these walls. The Tech Spec also includes three suggested wall types for meeting different levels of STC rating or physical hardening requirements. These are not the only wall constructions that will meet requirements, so there is wiggle room for you to design other options that will still meet requirements. However, as always the final design is up to the Accrediting Official (AO).

The requirements you have to meet will be determined by the unique risks your facility faces. For example, if the SCIF will share a wall with a location that could house foreign nationals, you’ll likely be looking at a higher STC rating requirement to prevent anything from being overheard.

Related: Understanding SCIF and SAPF Door Requirements

The General Requirements

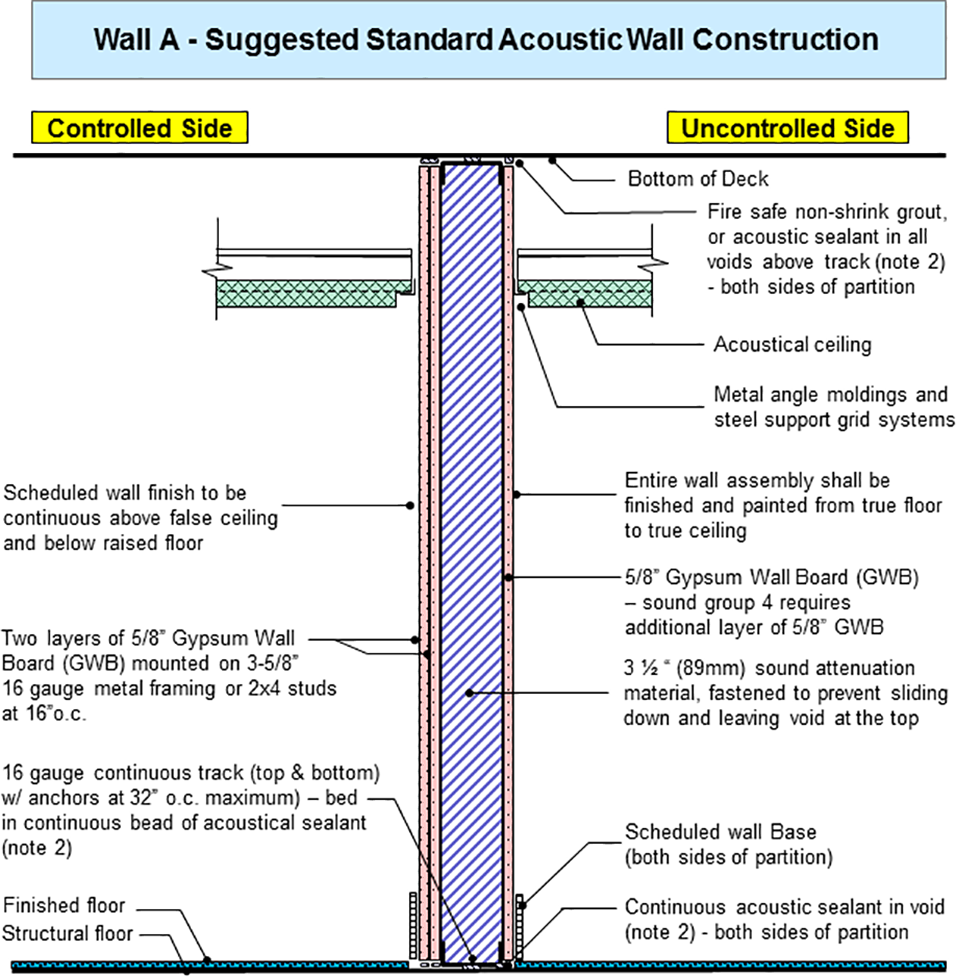

lays out the base line requirements in Chapter 3 Section C that all perimeter walls will need to meet, including a minimum of three layers of 5/8” gypsum wall board, acoustic fill, and staggered seams. Your requirements will differ based on factors like if classified information will be discussed, stored or processed within the facility. For SCIFs and SAPFs, the walls will need to meet a minimum of STC 45 rating. If your facility is under continuous operation, has strong Security in Depth (SID) or has closed storage, you may not need any further physical or acoustic protection.

The wall needs to be painted from true floor to true ceiling. Generally, the default is to paint it uniformly all the way, but some AOs may have a preference for how it’s painted. For example, they may want white below the false ceiling but black from the false ceiling to the true ceiling to make penetrations easier to see. Be sure to make your painting plan clear in designs so the AO can see it and let you know if they need any changes.

Meeting Higher Physical Hardening or STC Requirements

While all walls have acoustic protection in the form of acoustic sealant and fill, you will need a four-layer wall construction to meet a higher STC rating. RF foil may need to be added to the walls as a TEMPEST mitigation. There is foil-backed drywall on the market, but it is unlikely to be accepted as it has not performed well in testing. What TEMPEST mitigations your facility needs will be up to the Certified TEMPEST Technical Authority (CTTA).

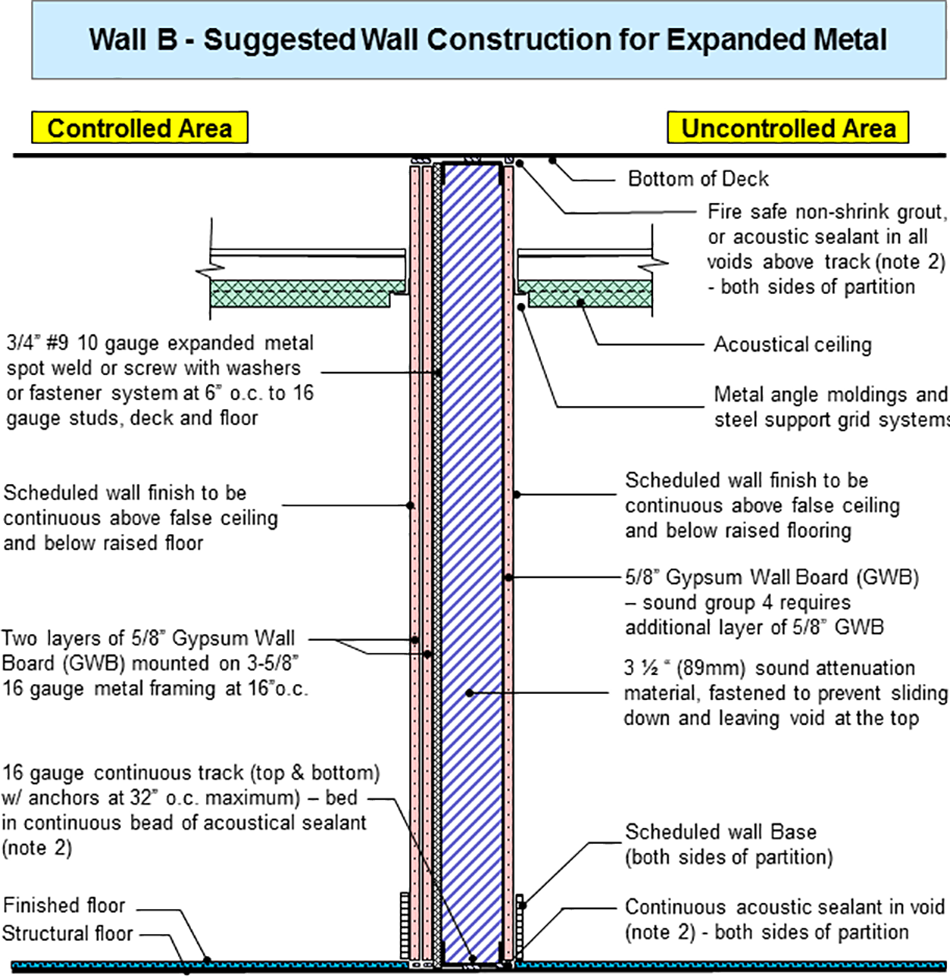

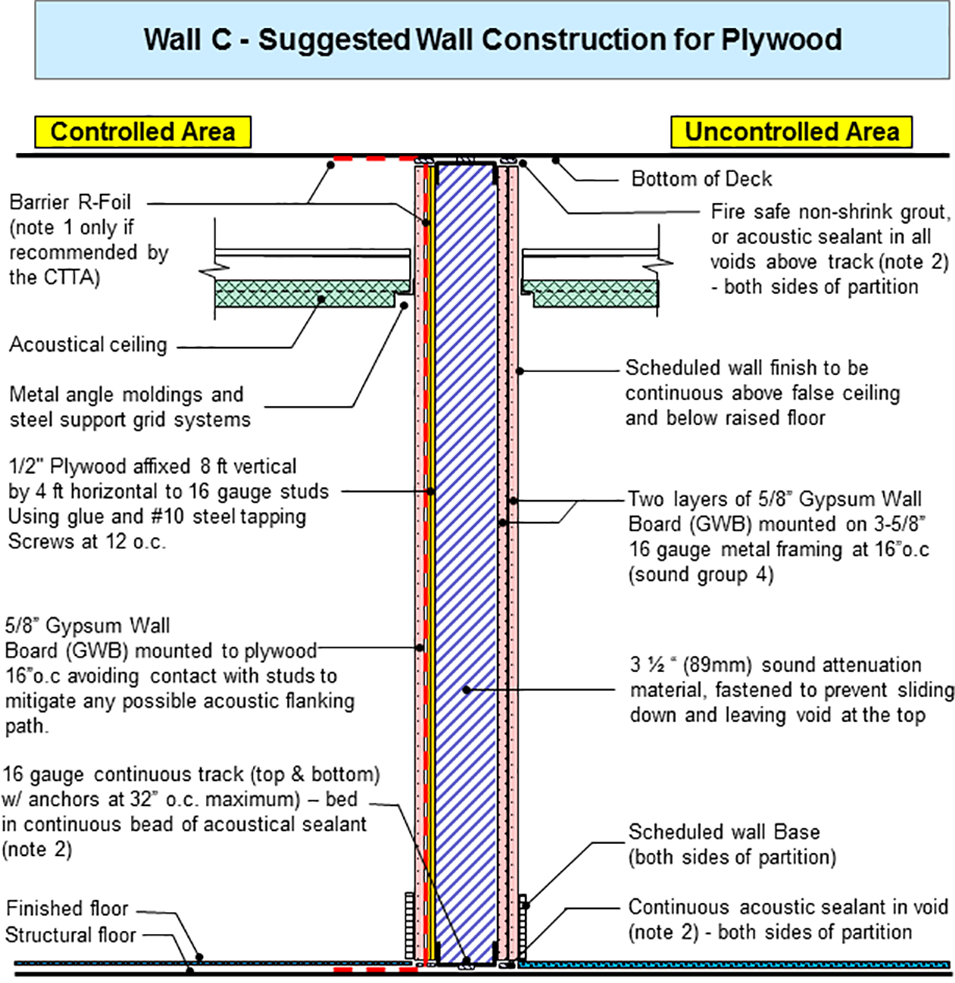

For physical hardening, you have the choice between ½” thick plywood and ¾” diamond mesh expanded metal. There are some benefits to choosing plywood over expanded metal. For one, plywood improves the assembly’s sound attenuation and can be used in place of a layer of drywall, while expanded metal cannot. While plywood may be a little more expensive than expanded metal in cost per square foot, it ends up being more budget friendly since it replaces that layer of drywall. Because utilities need to be wall mounted, plywood adds backing to the wall that makes the mounting more secure than if it were just in drywall.

RF foil can also be placed between drywood and plywood, whereas if the assembly has expanded metal, the foil must be between two layers of drywall. Expanded metal can be useful in a build where flammability is a concern, but fire-rated plywood is also available. AOs may have a preference for one or the other, however, so they’ll have the ultimate say in which material you use.

Your facility may also require further sound masking, such as sound transducers or wall-mounted speakers, to help increase acoustic protection. This will either be recommended by the AO during the design phase or as an extra mitigation after the walls are constructed.

The Suggested Wall Types

The three wall types the Tech Spec diagrams are referred to as Wall A, B and C. While these are just examples of wall constructions that will meet the acoustic and physical hardening requirements, some AOs may treat these exact wall types as required and will expect you to build one of these wall types.

Wall type A is a standard construction with no added physical hardening or acoustic protections beyond the requirements listed in the general requirements section above.

Wall type B adds expanded metal as a means of further physical hardening and covers the requirements for how to correctly install it.

Similarly, Wall type C adds plywood for physical hardening and covers the requirements. In the diagram for this wall type, you can see how the plywood replaces one of the layers of drywall. There’s a layer of drywall on both the controlled and uncontrolled side of the perimeter, and the plywood is added to the uncontrolled side.

If you want to learn more about how to properly construct perimeter walls or other parts of your SCIF, consider attending Adamo’s Development of SCIF and SAPF course. You’ll learn from our experts all the ins and outs of SCIF construction and hear real-world examples of how to meet Tech Spec requirements.