Understand ICD 705 acoustic requirements and avoid common mitigation mistakes

The walls of a SCIF or SAPF aren’t just protecting physical information; they also protect the conversations held within. A secure facility must meet a standard of acoustic protection determined by the Accrediting Official (AO). The ICD 705 Technical Specifications, or Tech Spec, lays out the acoustic requirements and mitigations necessary to prevent conversations from being overheard by someone outside of the facility.

Acoustic Requirements and Mitigations

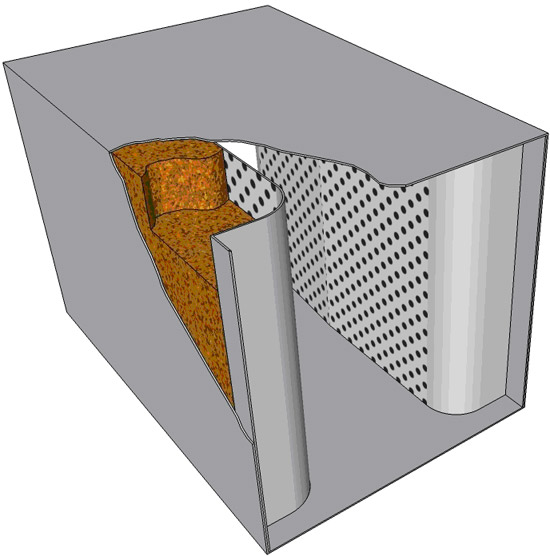

A wall with acoustic insulation

The AO will determine the Sound Transmission Class (STC) requirement based on if amplified sound will be used within the facility. Your facility will either need to be built to STC 45, also referred to as sound group 3, or STC 50, also referred to as sound group 4, in the case of amplified sound. For STC 45, loud speech can be heard outside of the facility but not understood, while normal speech cannot be heard at all. For STC 50, even a radio at full volume or a trumpet is barely audible outside the wall, if heard at all. Acoustic mitigations will be applied at the perimeter of the facility, and your perimeter walls are a key part of the acoustic barrier.

The Tech Spec gives three suggested wall types that meet different facility requirements, including acoustic requirements. One of the most important aspects of acoustic mitigation in wall construction is the multi-layered approach. An STC 45 wall has a three-layered assembly with one layer of drywall or plywood on the uncontrolled or unsecured side and two layers on the controlled or secure side. To bring the rating to STC 50, another layer is added to the uncontrolled side for four total.

The walls are filled with fastened insulation. When instructing a contractor on installing insulation, we recommend specifying that it must be mechanically fastened. This will prevent the insulation from slipping down within the wall and compromising your acoustic barrier. The walls will be sealed with acoustic sealant to ensure no holes remain.

While the three wall types in the Tech Spec are ways to meet your acoustic requirements, they are not prescriptive. If you have a different wall construction, like concrete, that will still meet the acoustic requirements, that is allowed under the Tech Spec as long as the AO approves.

Penetrations are also a key focus when building a secure facility. Pipes must be properly sealed with acoustic sealant all the way around. For HVAC systems, Z vents and sound baffles are both effective mitigations.

A sound baffle

Doors can be purchased as a complete assembly made to meet your STC requirements. So-called “doors in a box” come with a frame, acoustic seals, hinges, and necessary hardware and only need to be installed. However, the door is also a common weak point in perimeter construction and meeting acoustic requirements.

Common Mistakes in Acoustic Mitigations

Some contractors opt not to buy one of these door-in-a-box assemblies and try to create their own from a hodgepodge of manufacturers. We strongly recommend against this. Even if all the pieces you buy are rated for your STC requirement, once put together the assembly may not test to that rating, and we’ve found they typically don’t perform well.

Find a contractor who has experience in installing STC doors. Even when using a door in a box, if the door is not properly installed and sealed, it may not perform as it should. The sealant must be applied thoroughly and all the way around the door frame.

Acoustic sealant can cause issues across the entire perimeter if it isn’t applied properly, especially with pipe penetrations. There is no room for laziness or lack of attention to detail when sealing penetrations and walls. It’s worth double checking any seals before moving on to the next step. If after construction you still don’t meet STC requirements, there are some steps you can take to still get accredited.

Sound masking system

Supplementary Mitigations

The STC rating is the main way that the effectiveness of your acoustic mitigations is measured, but the AO might also require additional mitigations that do not increase your STC rating. One common example of this is sound transducer or sound masking systems. These involve installing speakers that play white noise at a volume that will cover the sound of speech and make it unintelligible outside of the facility. These systems would be used anywhere that there might be weaknesses in the perimeter, such as penetrations or doorways.

A second perimeter or stand-off distance might be added when possible, since the distance will make eavesdropping impossible. This may be an added perimeter fence outside of the facility.

An important part of acoustic mitigations is testing you can trust. Our team at Adamo uses top-of-the-line equipment and a meticulous testing procedure to ensure the most accurate data possible and determine your STC rating. Our team of experts will provide a comprehensive report that will empower you to address any weaknesses in your acoustic protections. Contact us today to learn how Adamo can help you receive accreditation.

An important part of acoustic mitigations is testing you can trust. Our team at Adamo uses top-of-the-line equipment and a meticulous testing procedure to ensure the most accurate data possible and determine your STC rating. Our team of experts will provide a comprehensive report that will empower you to address any weaknesses in your acoustic protections. Contact us today to learn how Adamo can help you receive accreditation.